There are multiple types of supply chains. A company can supply labor, finished goods, parts, supplies, materials, and more. No matter what your supply chain looks like, or what pieces of it your company is involved with, Oracle Supply Chain Management Cloud (or Oracle SCM Cloud) has the solutions you need. For the purposes of this article, we will focus on companies that sell or produce physical items.

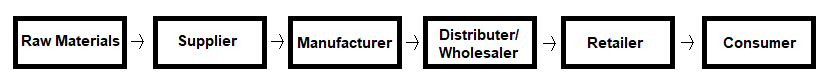

In the past, raw materials would be gathered and sold by company A. Company B would take those raw materials and turn them into supplies or parts for Company C. Company C would manufacture finished goods. Company D would then buy those goods in bulk to distribute to various retailers. Company E, one of the retailers, buys the product and sells it to a consumer. The following graphic illustrates what the supply chain used to look like:

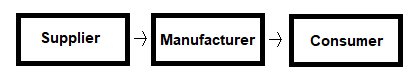

However, as online sales and companies gain greater traction in the market economy, there has been an increase in manufacturers selling products directly to consumers. This allows manufacturers to connect directly with their consumers and increase their profits while giving customers direct access to the full suite of products at lower prices than customers would see at a retailer. The following graphic illustrates what the supply chain looks like with online sales:

This shift effectively cuts the supply chain in half.

What is Oracle SCM Cloud?

[/vc_column_text][vc_column_text]Oracle SCM Cloud connects your supply network to business applications such as Supply Chain Planning, Inventory Management, Manufacturing, and Procurement in order to streamline business and outpace change.

The following list details Oracle SCM Cloud’s business applications and their capabilities:

- Supply Chain Planning

- Supply Chain Planning

- Supply Chain Collaboration and Visibility

- Inventory Management

- Materials Management

- Cost Management

- Financial and Supply Chain Orchestration

- Manufacturing

- Discrete Manufacturing

- Process Manufacturing

- Mixed-Mode Manufacturing

- Project-Driven Manufacturing

- Contract Manufacturing

- Maintenance

- Service Logistics

- Asset Management

- Maintenance Work Execution/Scheduling

- Work Order Costing

- Spare Parts Inventory/Procurement

- Preventive and Predictive Maintenance

- Project-Driven Maintenance

- Order Management

- Omnichannel Order Management

- Rapid Order Fulfillment

- Pricing Management

- Product and Service Configuration

- Global Order Promising

- Channel Revenue Management

- Logistics

- Transportation, Global Trade, and Warehouse Management

- Product Lifecycle Management

- Innovation Management

- Product Development

- Quality Management

- Configurator Modeling

- Product Master Data Management

- Procurement

- Procure-to-Pay

- Supplier Management

- Sourcing

- Contracts

- Business Network

Oracle SCM Cloud’s broad range of offerings gives you a one-stop-shop to brainstorm, create, test, manufacture, store, and fulfill orders on any given product.

You may be thinking, “I only make products, I don’t need all of those apps,” or “I only sell products, I don’t need all of those apps.”

BUT

There is always more to the supply chain than meets the eye.

Manufacturers and Oracle SCM Cloud

Let’s talk through an example.

You make the product, so you need Oracle Manufacturing Cloud. However, you also need to buy the materials to make the product, so you need Procurement to buy the materials and Inventory Management to keep track of them. Now that the product is made, you must sell it to someone! Whether you are selling direct to consumer or to a middleman, the product you just made has to go somewhere. Order Management can help you make sure your products end up in the right places.

Now let’s expand this example:

- If you have more than one supplier, you need to know how much to procure from each supplier at any given time. You will need Supply Chain Planning.

- If you need to keep track of the equipment used to make the product to ensure it is ready and in working order at all times, you need Oracle Maintenance Cloud.

- If you have more than one buyer, and you are responsible for the delivery of the product, you need Oracle Logistics Cloud.

- If you have to design and make new products to sell, you will need Oracle Product Lifecycle Management Cloud.

See how manufacturers need more than just Oracle Manufacturing Cloud? Let’s do a different example.[/vc_column_text][vc_column_text]

Retailers and Oracle SCM Cloud

A retailer sells products in multiple places and almost always keeps the extras in a few central warehouses. How do you keep track of what is where? You can leverage Inventory Management and Logistics and Order Management in the SCM suite. While you probably won’t ever have need for Product Lifecycle Management or Manufacturing, the rest of the Oracle Suite is yours to command.

You will need Oracle Procurement Cloud to buy the products for your warehouse. These items will be added to your inventory. From your inventory records, various stores can place orders from your warehouse to get product transferred from the warehouse to their retail store and Oracle Logistics Cloud will get it there.

Let’s say, for example, a product gets returned because it is broken. You can send it back to the manufacturer for a replacement product altogether, or you can use Oracle Maintenance Cloud to keep a variety of spare parts procured to quickly fix common product issues for the customer.

And to make sure your Procurement to Inventory to Order Management line runs smoothly, you would use Supply Chain Planning to monitor and adjust course as needed.

Finally, in the cases where your company contains all aspects of the supply chain, you definitely need everything!

Manufacturing and Inventory

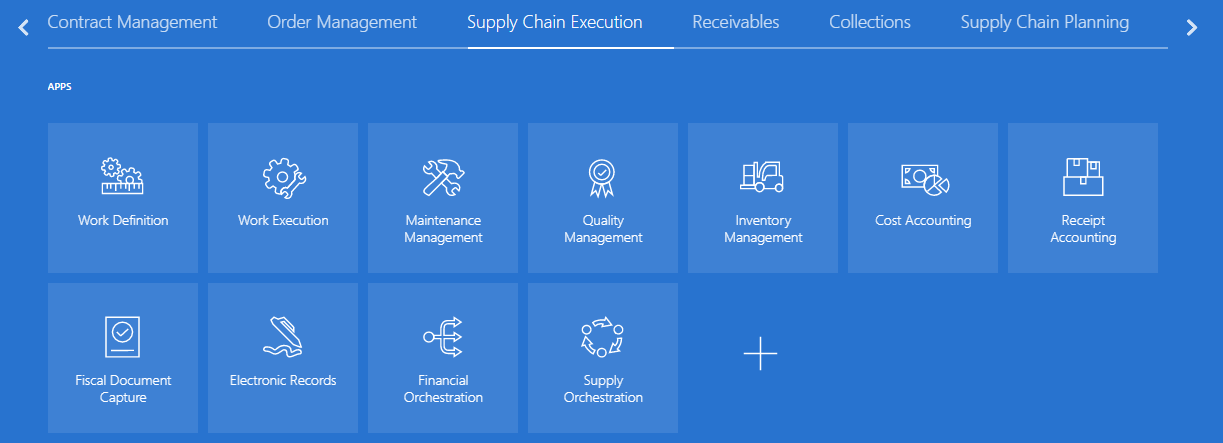

Let’s do a deep dive into two of the applications available: Manufacturing and Inventory Management. Why these two? They are arguably the most important apps to manufacturers and retailers, respectively. All companies with physical items are going to use most of the available apps as discussed above, but the applications that will most likely be used by the most people in any given company, are going to be Oracle Manufacturing Cloud and Oracle Inventory Management Cloud. Oracle groups Manufacturing work areas and Inventory Management work areas together under a single tab called Supply Chain Execution.

The following screenshot displays the Supply Chain Execution tab in the Oracle UI:

Oracle Manufacturing Cloud

Oracle Manufacturing Cloud is used to oversee and facilitate how raw materials are turned into products. Manufacturing is the link between Innovation Management and Inventory. Innovation Management is where products are envisioned and is part of Product Lifecycle Management Cloud.

Within Manufacturing, you can set up standard operations. A standard operation describes normal processes for your company’s manufacturing endeavors. For example, worker preparation for a clean room or lawn chair assembly.

These standard operations live in a “library” of sorts so you can easily add them to work definitions. A work definition defines how a product is made. This includes the necessary operations, materials, and resources.

You can have both discrete manufacturing work definitions and process manufacturing work definitions. In discrete manufacturing, a product is built from materials that can be taken apart again (like cars and furniture). In process manufacturing, a product is created from materials that will then always exist in that state unless further manufactured (like paint, clothing, drinks, or chemicals of any kind).

The three most used applications within Oracle Manufacturing Cloud are Work Definition, Work Execution, and Cost Accounting.

In the Work Definition app, you can manage your work definitions, standard operations, and work centers. Work centers are departments or production lines responsible for specific operations.

In the Work Execution app, you can manage work orders. Work orders are documents that tell work centers how much of a product to make. A standard work order is used when the standard work definition is used. A nonstandard work order is used for prototypes, repairs, upgrades, and customizations that would use a different work definition than usual.

In the Cost Accounting app, you can analyze and track how much money the company is spending on manufacturing. You can view costs individually or “rolled-up” to analyze the entire process cost.

Oracle Inventory Management Cloud

Oracle Inventory Management Cloud gives you comprehensive materials management, helps you optimize replenishment, determine costing, optimize profitability, and keep track of inventory.

Inventory management operates in real time, so balances, statues, and counts are always up to date. You can automate fulfillment options such as drop-ship, back-to-back and supplier-consigned inventory to streamlines business practices. You can also set alerts to notify you when inventory stock reaches certain minimums or maximums and coordinate inventory with supply and demand planning.

With Inventory Management you can designate a supply as one of the following:

- Buy, meaning it’s procured from an external supplier

- Make, meaning it’s made in house

- Transfer, meaning it’s transferred from another warehouse

- On Hand, meaning you have it in the warehouse already

You can also include consigned materials in your inventory. Consigned materials being inventory that is not owned by you but kept in your buildings by your company.

Unique factors to help with Inventory Management:

- Cycle Counting – you can define and adjust certain items to be counted cyclically rather than all inventory all at once

- Inventory Reservation – Link a supply source to a demand source to ensure there is always enough supply for the demand, particularly useful with parts

- Supply request – most replenishment needs can be automated; however, a supply request can be created to request the creation, update, or cancellation of an order outside of the normal automated schedule you created.

Have more questions about SCM?

Good news! We can help with that too. While this article was meant to demonstrate how necessary SCM is to a business, our courseware contains all the documentation and walk-through tutorials you may need to actually implement and maintain your Oracle SCM Cloud software. We can make custom content too!

You can get all of this and more with ENGAGE by Maverick. ENGAGE is Maverick Solutions’ subscription-based training content on all Oracle Cloud applications. It is fully customizable, comprehensive, and available 24/7/365. If you want to know how Maverick Solutions can fit into your organization’s current or future Oracle projects, speak with one of our training experts today!

The article was written for Oracle release 21A. Due to the nature of Cloud software and updates, this article may no longer be accurate. If you would like access to the most up-to-date version, please reach out to our team to learn more.